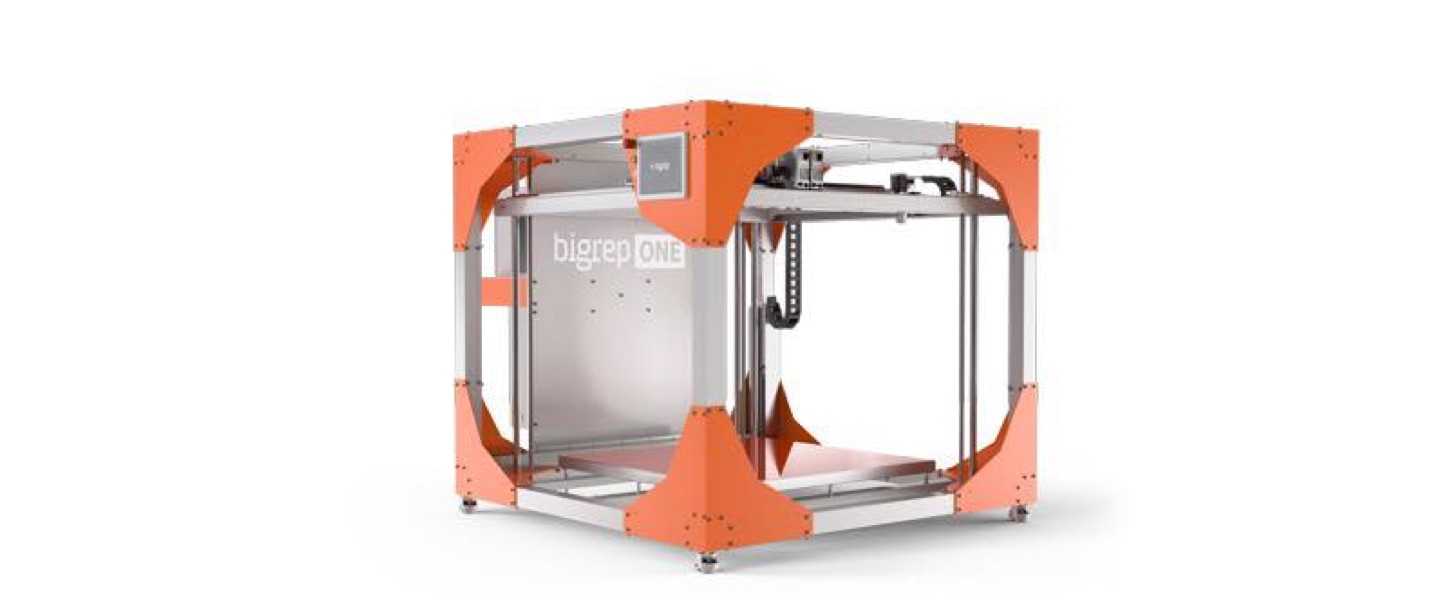

3D PRINTER 3D PRINTER

Realizing images faster and with more accuracy

Due to the diversification of molding methods and materials, the applications of 3D printers are expanding from “rapid prototyping” to “mold and jig manufacturing” and “final product building.”

To satisfy a wide range of customer needs, RDS has introduced three types of 3D printers – FDM machines, powder molding machines and metal molding machines. In addition to resin such as ABS, the latest modeling machines are also compatible with metal materials such as aluminum and titanium. In addition, not only is it possible to perform finish processing, measurements utilizing such things as three-dimensional scanning is also possible. Together with comparing and evaluating differences with customer data, we provide support for partial intervention, clearance, and optimization simulations of processing settings.

RDS currently aims for further application of 3D printer technology, such as working to create a wide range of environmentally friendly solutions for clients with emphasis placed on unique material development, such as the development of unique materials which are serviceable in the human body.

* Powder shaping (sPro60 HD-HS)

Powder shaping is a type of 3D printer that irradiates resin powders with laser to combine them. In comparison with other 3D printers for resin, it can produce components with high strength and is thus used for evaluation or fitting tests, for jigs, and for some small mass-production products. The sPro60 is a world standard machine for powder shaping and a type of equipment that allows you to handle multiple kinds of materials easily because of its manual operation.

* Metal shaping (ProX300) corresponding to aluminum and titanium

Metal shaping is a type of 3D printer that irradiates metal powders with laser to combine them. It is a spotlighted technology spreading not only for prototype use but also for the adaptation to mass production related to scientific industries such as automobiles, aircrafts, or medical sciences. Because our own ProX300 feeds powder materials while applying appropriate pressure to them with a roller using an original roller wiper layering system, it can optimize the laminated thickness and density of material. It can thereby suppress variations in quality and use finer metal powders, and thus it can make the surface roughness and minute shaping much more precise than ever.

* FDM shaping (FORTUS400mc)

Corresponding to ULTEM*9085, ULTEM*1010, ABS-M30, ABS-M30i, ABS-ESD7, PC, PC-ABS, PC-ISO, PPSF, and Nylon 12 resin. You can choose any material from not only general-purpose resin ABS-M30 but also Polycarbonate (PC) of high strengthened and high heat-resistant (approximately 140 degrees Celsius) resin, PC-ABS with impact resistance, PolyPhenylSulfone (PPSF) of chemical resistant and high heat-resistant (approximately 200 degrees Celsius) resin, flame retardant Polyether Imide (ULTEM*9085) resin used also for aircraft interior parts, Nylon 12 with high strength and fatigue resistance, and so on.